Small Scale Precision Agriculture

Shaylee Strawberries were looking for an affordable approach to precision agriculture for their four hectare strawberry farm. We delivered an RTK machine guidance system that works for all his tractors.

Background

Shaylee Strawberries supply fresh strawberries to retailers and sell fresh and frozen fruit, jams and ice-cream direct from their farm-gate café on the Atherton Tablelands. The owner, Joe Barletta came to Mangoesmapping late in 2019 with a question: “Is there any way I can prepare straight beds for my strawberry plants, without spending big dollars on a machine guidance solution?”.

We discussed Joe’s compact strawberry farming operation, that occupies only 4 hectares, and his challenge of investing significant sums on machine guidance hardware for relatively small machinery. We reviewed what affordable options were available to him at short notice. We had an imperative to get Joe’s trial set up in time for him to evaluate as he undertook the annual task of forming up this year’s strawberry fields. I know what you’re thinking right now… contrary to the well-known Beatles song, strawberry fields don’t last forever.

As a reseller for the increasingly popular Emlid Reach RS2 GNSS RTK receiver, Mangoesmapping prepared a ‘minimum viable product’ machine guidance solution using a ‘digital lightbar’ Android app for Joe, including his very own GNSS RTK base station – no costly annual StarFire subscriptions here!

An Affordable Approach

To undertake the trial, we used some of our rental equipment, and equipped Joe with:

- a GNSS RTK base station (Emlid’s multi-band Reach RS2) – $3799

- a GNSS RTK rover to mount on his tractor (another Emlid Reach RS2) – $3799

- an Android tablet ($400), equipped with the Field Navigator and Lefebure

- NTRIP client apps (free), and

- some ancillary RAM Mount hardware to mount the gear on his tractor ($200)

Joe helped out by building an elevated mount on one of his sheds, to hold the RTK base station. He also supplied permanent power from a 12v transformer, protected from the weather inside his shed.

To make the most of the new levels of location accuracy available on Joe’s farm, we coordinated the RTK base using nearby survey benchmarks. With this, his tractors position is precisely known, and accurate to real world coordinates. This has the benefit of allowing tractor positioning overlaid on aerial imaging like Google Maps, running on the Android tablet in his tractor cab. Additionally, this supported on-farm data collection (eg. asset and farm layout data collection), to assist with Joe’s Freshcare accreditation property plan and associated mapping & audit compliance.

Undertaking The Trial

Establishing the RTK Base

The first step in the process was to mount the RTK base on Joe’s shed and connect it to permanent power. This was made easy as the Emlid units can handle from 6-40 volts, and can tolerate high amps – you can even connect them to unregulated solar panels. Fortunately, Joe had an old 12v 15A transformer lying around so we ran a cable from that up to the RTK base station mount.

As part of this trial, I was eager to validate Emlid’s Reach RS2 IP67 rating with a waterproofing torture test. The base station was left running on the pole throughout the wet season. Here, in the aptly named Wet Tropics, rain is often measured in metres…

The Reach RS2 performed well, and did not miss a beat despite having both the power and LoRa antenna ports open the whole time – and enduring the monsoonal rain that delayed Joe’s ‘precision bed-forming’ by weeks.

The RTK Base was coordinated by configuring it to receive corrections from the RTK Rover, which we temporarily established using a tripod on a nearby benchmark and configured it to broadcast a correction to the long-term base on Joe’s shed. Adopting this ‘traverse’ survey method, we could establish a long term RTK Base in a secure location inside Joe’s farm.

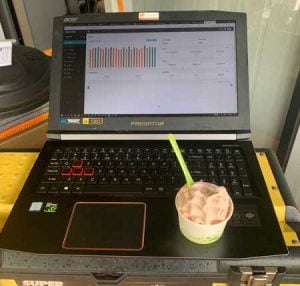

It was a warm humid day while we did this, so Joe kindly offered me a sample of their popular strawberry ice-cream to sample.

Not only was the ice-cream delicious, I think it also helped to cool the laptop while I let it melt enough before I ate it, to avoid brain-freeze.

Pimp My Tractor

The next step was to set up the gear on the tractor. As this was only a trial and thus a temporary deployment of the gear (which due to the persistent wet weather ultimately extended over 3 months), all the gear was mounted using RAM suction and magnetic mounts.

The RTK Rover that delivered survey-accurate positioning to the lightbar app was powered only using its battery, to save on cabling effort. We could do this due to the long lasting 16 hours operating capacity of the Reach RS2’s internal battery. At night, Joe took the RTK Rover inside and simply charged it with a USB cable.

The RTK Rover used its internal LoRa 918 MHz radio to receive RTCM3 correction messages from the RTK Base. The RTK Rover’s corrected coordinates were then streamed from the rover in NMEA format to the Android tablet via Bluetooth. This is all configured in the easy-to-use Reachview software that is included free with every Emlid GNSS receiver.

By this point, we had the RTK Rover mounted on the tractor, receiving corrections from the RTK Base and sending a constant positioning stream via Bluetooth to the tablet inside the tractor cab.

The Tablet we used was a 5-year old Samsung Galaxy Tab S 8”. Most modern Android tablets are likely to be suitable. We can recommend selecting one with a bright screen to make life easier for the tractor operator.

To take advantage of the incoming Bluetooth positioning stream, we used the Lefebure NTRIP client app to ‘mock’ the tablet location. Lefebure’s NTRIP app allows the tablet to assume the location of the RTK Rover. This resulted in every location-enabled app on the tablet using the incoming accurate positioning data, rather than the tablet’s internal consumer-grade GPS. It’s pretty cool when you open Google Maps on the tablet and that familiar blue circle around your location (that communicates location uncertainty) just disappears! When the RTK Rover had a ‘fix’ solution (ie. position was determined to a high degree of accuracy), the Lefebure app was consistently reporting accuracy (positional uncertainty) of 2 cm, relative to the location of the base.

To perform the actual ‘lightbar function’, we used a free Android app named ‘Field Navigator’. It took a little bit of getting used to, however after we marked up the extent of the fields and ran the first AB line, the app did the rest, and set up the remainder of the AB lines and delivered a ‘digital lightbar’ on the tablet screen to guide Joe’s steering.

When I checked in with Joe during the trial, the first thing he said was that “the GPS gear is the most reliable thing in my setup. I get more problems with my equipment. If everything worked like your solution, I’d be done already”. He also later admitted that he’d gone on a bit of a learning curve with the gear, to understand how the gear worked. On his first day of the trial, he struggled to identify why he could not get the RTK Rover to ‘fix’ (determine a highly accurate position) while he was doing his pre-start checks with the tractor parked in the shed. Once he got out of the shed, it fixed in seconds.

When asked if he trusted the gear, Joe said he didn’t at first and kept thinking he was off-course. After wasting thousands of dollars on plastic mulch that had to be re-laid, Joe learned to trust the directions from the tablet instead of following his intuition. He said he would have been better off blacking out the windscreen at the start and just following the tablet instead!

Of course, no modern story escapes without a mention of Covid-19 impacts. Joe’s strawberry plant supplier had issues shipping Joe’s new plants up to him from Victoria, right in the midst of the high-growth rate of the first wave of Australian cases. These initial supply delays, along with the imperative to get partial shipments of plants in the ground as soon as they arrived extended the precision bed forming trial, which was already impacted by severe wet weather events.

Wet weather conditions during the trial meant Joe had to work the beautiful red basalt derived soils of the Atherton Tablelands while it was wetter (and thus heavier) that he would have liked. As a consequence, Joe used a bigger tractor and was able to easily relocate the RTK Rover and Android tablet hardware without any hassle. The only thing he had to do was add a USB outlet to the cigarette lighter/12v power outlet on the bigger tractor, to provide power to the Android tablet.

At the end of the trial, Joe and I caught up at my home, and we debriefed on the project (while reviewing my pandemic veggie gardening efforts). Joe said he was working under such time pressure, that he ended up forming up some of the beds at night. They had never done that at the strawberry farm before and Joe said he could only do this because he had the lightbar solution on his tractor.